We know that most CO2 emissions come from the manufacture of systems, appliances and machines of all kinds, and I’m not including the other pollutants that these industrial processes release. For computers and mobiles, it’s 70%, for cars, it’s about the same.

On the other hand, we keep hearing or reading about the urgent need to relocate industrial processes, to reduce our dependence on China. Nicolas Dufourq’s recent book is a brilliant plea for a capacity that only needs to be called upon.

There is no need to elaborate on the masochistic nature of such contradictory injunctions. We live in a production economy, industry, which, to prosper, must produce, while we must consume. It is wrong to stigmatise the consumer society, when we are in a production economy that is constantly developing supply.

If we try to put some rationality into this approach, and to resolve this deleterious contradiction, we can agree that the challenge is to prolong the use of a system, a device or a machine as much as possible. How can this be achieved? Well, by making the switch, the transformation of this economy of production into an economy of use.

In a production economy, the margin of the company increases according to the number of goods produced, and therefore of systems produced, whereas in the economy of use, which is fundamentally based on a service economy, the duration of the good or system increases the margin of the service provider.

At this point, we can already see that, in this context, the service orientation of France in the 1970s is suddenly proving to be an advantage, and that the advocates of industrialisation who argue for the development of a production economy are proving to be at cross-purposes.

How do you make a transformation that is in fact very radical? The economy of use is an economy that mobilises even more specialised skills than the industrial economy. It relies on the know-how of operators who will have to sell the use of systems, devices or machines, and commit themselves to the service and benefits they provide. They will have to guide producers to adapt their products, manufacturing methods and design.

On the other hand, if consumers are not encouraged to turn to these operators, the dynamic will not take off. So how do we proceed? By taxing the buyer according to the length of use of his previous system, appliance or machine, he is encouraged to keep it for as long as possible, and, to achieve this, he will be inclined to contract with an operator who, thanks to his experience, will be able to provide him with this service and refrain from acquiring a good whose lifespan he will not be able to manage.

The result will be that either manufacturers will restructure to become operators themselves, or they will have to depend on operators who will act as intermediaries with their customers. This approach will profoundly transform the production system, as goods will have to last and delay their obsolescence. Industrial value chains will evolve, with more emphasis on use than on production.

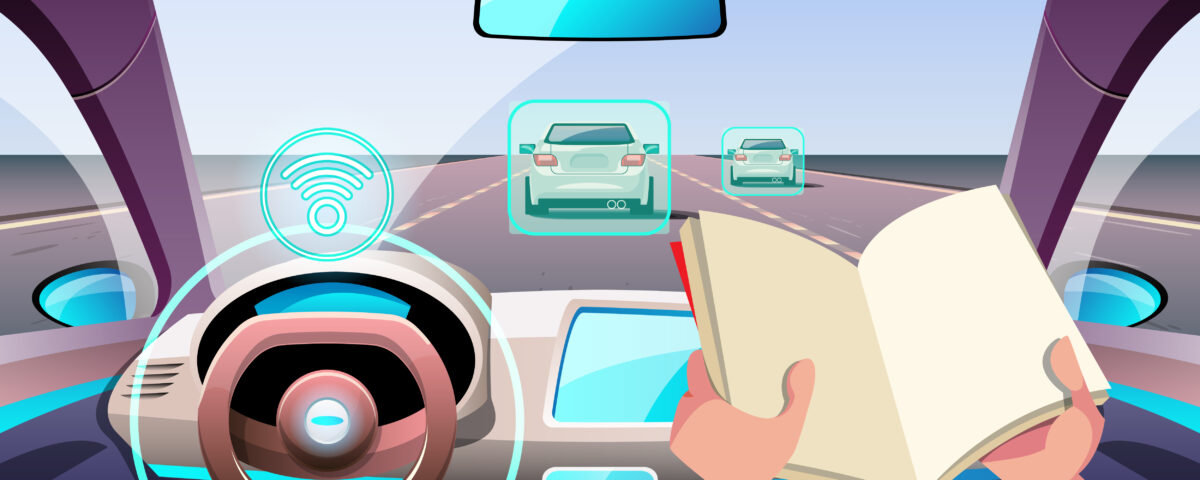

For example, the autonomous car will be a shared car, it will pick up users on demand, it will be shared between several users and it will drive all day long, instead of staying in the garage, as cars do now. This approach will change the dependence on the Chinese factory which has found its importance in the production economy.

It is clear that the idea of taxing goods according to their duration of use hampers international free trade agreements. Without a political powerhouse like Europe, this shift cannot be envisaged.

It must be successful because it represents the future of the West, but also a train of development to be taken by the emerging countries, vis-à-vis countries that are very much engaged in a production economy that no longer meets the needs of the planet.